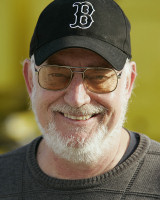

The Way It Is/ A look inside Ford's GT projectby Gordon Kirby |

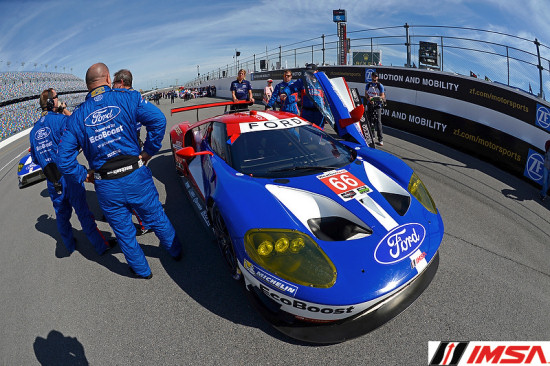

Ford's pair of brand new Ford GT Le Mans cars run by Chip Ganassi Racing made their debut at last weekend's Rolex 24 Hours. It was a tough start as both cars ran into an infuriating series of gearbox and electrical problems. But Ganassi's drivers and team kept plugging away and both cars made the finish one of them finishing a distant 31st, 46 laps behind, and the other classified 40th, 176 laps down.

Ford's pair of brand new Ford GT Le Mans cars run by Chip Ganassi Racing made their debut at last weekend's Rolex 24 Hours. It was a tough start as both cars ran into an infuriating series of gearbox and electrical problems. But Ganassi's drivers and team kept plugging away and both cars made the finish one of them finishing a distant 31st, 46 laps behind, and the other classified 40th, 176 laps down.

It was dispiriting for the cars to hit so much trouble after an exhaustive and largely trouble-free test program over the last half of 2015. But the Ford GTs were entirely competitive in a hotly-competitive category featuring factory or factory-backed teams from Corvette, Porsche, BMW and Ferrari, and clearly, the Fords have the potential to win races. The goal of course is to win the GT LM class at Le Mans but the cars are also bringing some fresh blood and added interest to IMSA's Weathertech SportsCar Championship. It was encouraging to see a good crowd at Daytona last weekend. Many of them were Ford fans and there was plenty of interest and enthusiasm for the cars among fans I spoke to in the garage area. Going into the weekend I discussed the development of Ford's GT project with Bernie Marcus who is Ford Racing's chief aerodynamicist and Larry Holt the vice-president of MultiMatic builders of the cars.  © Mike Levitt LAT/USA "The decision was made to design and build a mid-engined super car because that's what you've got to have to be eligible to run GTLM," Marcus says. "Ford didn't have any cars like that which could have been adapted properly and was likely to be competitive. So the decision was made to do a mid-engined super car. The next big thing was Ford's marketing department wanted an Ecoboost engine to be part of the program so it has a V-6 turbo engine. "The project was sub-contracted out to MultiMatic. They had been selected to do the road car and had the capability to build a race car so it was very logical to go with them. "We worked very closely with MultiMatic on all the aero development. We did it at the ARC wind tunnel facility in Indianapolis. We used their CFD because they have a very good CFD program that compliments their rolling road wind tunnel. The car was done under the big umbrella of MultiMatic but I managed the operation in Indianapolis." MultiMatic's Holt gives full credit to Ford's global vice-president of engineering Raj Nair for bringing the concept to life. "Ford came and knocked on our door and asked if we were interested, and of course we were," Holt said. "We were fortunate that we've got a good relationship with Raj Nair. There's no question that he's the visionary who made it happen. He's a highly technical guy and is in charge of all things engineering worldwide. He knows all the ins and outs of this program and is the guy who made it happen. "To get Ford Motor to do something like this is amazing. There's no way that car would look like it does and perform the way it does without tremendous co-ordination between MultiMatic and Ford Motor." Holt emphasizes that no single individual is responsible for the new Ford GT's design and engineering. "Everybody always looks for the single individual who's responsible," Holt says. "It goes back to idea of the genius working at the drafting board. People want to know who's the Adrian Newey or Colin Chapman or Eric Broadley of this project. But in this day and age, there isn't that guy. I don't want to make it sound like it's design by committee, but it is a very complex thing. "The days of a guy working at a drafting board laying out a car are long gone. It's now truly teams of people. A guy like Adrian Newey makes a sketch but he's got fifty people working for him who then put the stuff in CAD." Bernie Marcus discussed the car's aerodynamic development. "It has some resemblance to the original GT-40 and to the revival edition from 2004," Marcus said. "But that car was not suitable for racing. It's architecture and shape didn't allow you to make any downforce. "We got the styling studio involved to generate some shapes. They came up with some different themes and we did some initial CFG studies on these themes. We worked on that for about six months and one theme was selected which was very close to what you see today. Then we started the aero development process. We worked first with scale models, then in full size. "We had a couple of design engineers and a couple of model makers plus a CFD guy working full-time on the program. There were fix or six people working on this program in Indianapolis the entire time until the middle of last year. The total time frame was about two and a half years from when we started to Daytona today. "Obviously, the main goal for this whole project was to go back to Le Mans. We've tested the Le Mans kit on the racetrack and we've got a lot of wind tunnel data. But in order to run Le Mans you've got to do the entire WEC and in order to get the marketing value in North America you need to run the IMSA series which means you run on all types of tracks.  © Mike Levitt LAT/USA MultiMatic's Holt commented on the vast amount of work that went into the project. "It's been a huge effort and I mean huge!" Holt exclaimed. "It's been going on for more than two years from the beginning of the conception through today. We really sunk our teeth into it. There was a year of development and planning, working with Ford on both the road car and putting the race car together. "At any one time we probably had up to 60 or 80 people in total and that's just a part of it because Ford has had a massive resource applied to it as well. There was also what we call a full service supplier base that has worked on the project as well on things like gearboxes. Ford has had huge resources working on the project. "The engine has been developed half and half between Ford's Performance Department and Roush-Yates. There is a distinction between the road car and the race car side but there's a lot of cross-over because they were done in parallel. So when you look at all of the suppliers that contributed to the project it numbers in the hundreds of people. "At any one time we've had 40 or 50 engineers on it. They weren't all dedicated to the racing program because some of them worked on the road car as well. I would say in total we had 120 to 140 technicians and people working on the project. So again, there's been a huge cross-over." As Holt says, MultiMatic has been flat-out developing and building the new Ford GT road cars as well as the race cars. "The chassis is a carbon fiber tub which is identical for the road car and the race car," Holt said. "It was developed by a group of guys who were very connected to all of the things you need to do for a road car as far as crash and homologation and all that stuff. But the development of the race car was integrated together with the road car with our race car guys under George Howard-Chappell's guidance and Julian Sole, Lola's former technical director, who has worked for us the past five or six years. "I think doing these things in parallel is unprecedented. We did a road car and a race car in parallel and we took some advantage from that because we had some freedom in some areas and none in others where it had to be exactly like the road car. In some areas we needed co-operation to do some things because there could be a million reasons why you wouldn't do certain things for a road car like you would a race car. "Some people have said we built a road car and turned it into a race car, but that's bullshit. That's not even something you can do in this day and age. For one thing, the race car doesn't require any durable homologation papers as far as crash testing. "So when we went into it we had the freedom of being able to do things the way we wanted. Actually, it's quite straining putting together all the road car and race car stuff. The resources of the Ford Motor Company are way beyond Multimatic. Ford has had hundreds of people working on it as well as many people at Roush-Yates. So again, it's been a huge project." Holt also talked about the depth of talent MultiMatic enjoys. "Peter Gibbons has worked for me since he left Michael Andretti's team five or six years ago and Mark Handford has also worked for me for about fifteen years. And of course, Julian Sole was the technical director at Lola. So a lot of big name guys have worked on this project and that's a challenge in itself. "When you've got that much talent, they all have their ideas of how to do things, and you also have a road car team working on it for Ford and a design studio making sure it doesn't turn out ugly. So it becomes a massive co-ordination effort and that's where myself and George and few other individuals have to steer it and keep it on the right track." Multimatic employs 3,000 people around the world, including 500 engineers. Holt says 200 engineers work at MultiMatic in Toronto, another 250 at his facility in the UK, plus 20 in Detroit, ten in Prague, and a few in Stuttgart. Dynamic shock absorbers are among many products MultiMatic designs and manufactures.  © Mike Levitt LAT/USA "MultiMatic was started in 1984 and '85 by Pete Czapka and he still owns the company. Peter started by bidding on manufacturing jobs for the auto industry and in my opinion he is the best manufacturing guy in the business. He hired the right people and got some good business going. Peter had a vision as well. He didn't just want to sell manufacturing processes. He wanted to sell product. "But then the industry changed quite significantly. The OEMs were starting to demand that the suppliers actually design the products that they make. That wasn't Peter's thing, but that was my background. I wanted to design my own product and Peter wanted to manufacture and sell the product. "So we came to an arrangement. The way things used to be in the industry was that engineering was subservient to manufacturing. We looked at it and in 1988 I started an independent organization which was completely separate and autonomous from the manufacturing side. We had the freedom to do whatever engineering work we wanted to do to generate a profit. "But it was also about enhancing our brand and eventually developing low-volume technologies that we could see growing into a product that differentiates ourselves in the high-volume business. "We went from five people in 1988 to 500 people today. After Lola went out of business I ended up taking over the Lola brand and it brought us people like Julian Sole and George Howard-Chappell." Multimatic Motorsports won the LMP 675 class at Le Mans in 2000. "That was definitely one of our proudest moments," Holt grins. MultiMatic also won the inaugural Daytona Prototype class at Daytona in 2003 and the GT2 class at Sebring in 2006 as well as Grand-Am championships in 2002, 2005 and 2008. "We are proud to be Canadians," Holt says. "It's tough to do this kind of thing in Canada, which is a country that's not generally viewed by the world to be a high-tech country. People think of Canada as a place where we're chopping down trees and mining stuff out of the ground. But there are some great universities in Canada and some great engineering business success stories. Still, it's a struggle. "The Toronto Star's Wheels section called us the 2015 Automotive Newsmaker of the Year because Ford announced we were going to build the GT in Toronto. That made both Peter and I a little uncomfortable because we're not high-profile guys. We're not newsmakers." Holt believes the GT Le Mans car has the capability to win races this year. "You'd have to be a pretty arrogant guy to predict it was going to win because racing is a cruel sport where anything can happen," he remarked. "But you can say that technically we've given it every advantage to win. Of course, you can step on yourself in some way or you can get off the track. The driver can screw-up or somebody else can run into you. But given the opportunity the car has the technical capability to win. I can assure everyone of that.  © Mike Levitt LAT/USA "And in the meantime," Holt adds with a grin, "we also run our Mustangs and we're still winning races." Indeed, Scott Maxwell and Billy Johnson won Friday's Continental Tire race at Daytona aboard MultiMatic's Mustang. Maxwell and Johnson also did all the initial testing of the Ford GT Le Mans car. "The first time we ran it was last spring," Maxwell said. "I've tested a lot of out-of-the-box cars and I was the first guy to drive the car. You always know pretty quickly, just through experience, whether it's going to be a dog or not. We weren't near the limit. We were just shaking it down but my gut told me that this was going to be a good car. It just felt right. "I did most of the testing through the first two months and then Billy jumped in through the early fall before the first car went to Ganassi and they started taking it down the race-tuning path. Billy and I did a lot of durability running." Bernie Marcus was pleased with the testing results prior to last weekend's race at Daytona. "Everywhere we've tested the car has done exactly what it was supposed to do according to all the wind tunnel data and simulations done by us and MultiMatic," Marcus said. "So far, so good. "I've been to most of the tests to make sure if there were any aero or cooling issues. We had to work on a couple things early in the test program but other than that the testing has been really good. "We were right on the pace with the other GTLM cars when we tested at Daytona and I'm really happy with the way it's worked so far. But of course, anything can happen in motor racing. The ten cent part can put you out of the race and we won't really know where we stand until the end of the race. "Ganassi's team is an excellent team and we've worked with them on the DP cars the past two years. So we have a great working relationship with them and they're doing a very, very good job." Added Marcus: "At the moment they're building the WEC cars at MultiMatic in the UK and they'll start testing those cars early in March. The FIA Prologue test at Paul Ricard over Easter weekend will be the first time we'll run the car in Europe against the European teams." Daytona proved a rough start for Ganassi's Ford GTs, but given the depth of resources behind the project I expect them to soon be running trouble-free and challenging the Corvettes, Porsches, BMWs and Ferraris for wins. |

|

Auto Racing ~ Gordon Kirby

Copyright ~ All Rights Reserved |