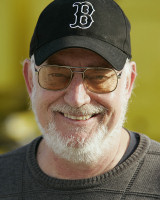

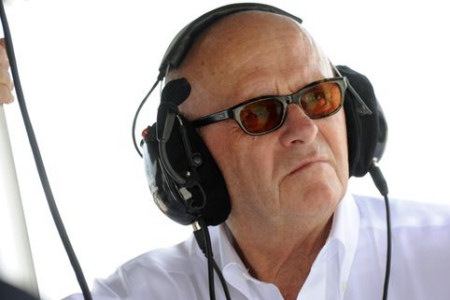

The Way It Is/ Derrick Walker on IndyCar's 2014 safety improvementsby Gordon Kirby |

The Verizon IndyCar series kicks-off in St. Petersburg next weekend and while IndyCar's Dallara DW12s look the same as they have the past two years many detail changes aimed at improving safety have been made under the skin over the winter. These include additional side impact protection, refinements to the cockpit surround and development of a steering damper unit. Last week I discussed these changes with Derrick Walker, IndyCar's president of competition and operations.

The Verizon IndyCar series kicks-off in St. Petersburg next weekend and while IndyCar's Dallara DW12s look the same as they have the past two years many detail changes aimed at improving safety have been made under the skin over the winter. These include additional side impact protection, refinements to the cockpit surround and development of a steering damper unit. Last week I discussed these changes with Derrick Walker, IndyCar's president of competition and operations.

"The biggest thing we looked at were safety-related issues," Walker said. "Side impact additions to the chassis came out of accidents that have happened before that highlighted the need to look at that. We went back and looked at the criteria the car was built to and reviewed what the FIA's impact numbers had been in the past. "We went back to the numbers and looked at accidents that have happened and came to the conclusion that we really needed to up it. So we worked with Dallara to produce some add-ons to the chassis. We wanted to do it without making major, costly changes that would obsolete the existing chassis. Dallara did some tests and came up with some good safety additions to the chassis." Included are foam-filled carbon fiber panels bonded to the exterior and interior sides of the cockpit, a carbon fiber reinforcement ring added to the cockpit opening and a modified headrest with a layered Nomex covering replacing the old, harder Kevlar piece. Walker pays tribute to Dallara's interest in doing the right thing to improve safety in partnership with IndyCar.  © LAT USA "We've mandated all of these changes. Every car that races this year will have to have these modifications made to them. Dallara has agreed to modify every car for the same price for a new car so any safety additions to a new car will not cost an additional fee. "Dallara have got to make the stuff and make the modifications so it's costly to them. It's not something they did wrong. They built the car to our specifications but we've now got some data with the benefit of hindsight and they've come to the table and agreed to modify the chassis. "It's been a good collaboration with Dallara going at it with the best intentions. Dallara always gets a whack from the team owners and some people in the media, but I have a lot of time for Dallara. To Dallara's credit they're one of the few companies out there who know about Indy cars and are willing to come to the table and try to work with us rather than trying to go for the jugular and try to charge us money as soon as we open our mouths, as everybody thinks they do." Walker says Justin Wilson's accident at Fontana at the end of last year spurred IndyCar to develop the foam-filled carbon side panels which are said to increase the side impact integrity of the chassis by 60 percent. "The oncoming car that hit Justin basically squeezed the chassis and because he is fairly big across the hips it squeezed his seat," Walker commented. "There are carbon fiber panels either side of the driver inside the cockpit that were just hollow sections and our boys worked on it and came up with some really good high density foam to fit inside those panels which add a lot more compliance for a driver. Putting foam in there adds another layer of absorption before the loads hit the driver's hips." Walker also discussed the improvements to the DW12's headrest and cockpit surround. "When I came on the job there was already some work going on about looking into improving the collar. In the speedway configuration the driver doesn't have a lot of room between his helmet and the collar because there's extra padding in there and he leans his helmet against the collar in the corners. "However, on a road course you have a lot more gap because the drivers turn their heads when they're turning into the corners and their heads and helmets move through a much greater space in the cockpit. So in the road course version there's a gap between the driver's helmet and the collar and when the driver's head would hit the collar it really wouldn't deform enough.  © LAT USA "The tests were already underway but they were accelerated when we looked at more video and listened to other comments from the drivers. We've come up with a softer, more compliant collar which works really well. Some people have expressed a desire to see a speedway version that could also be more compliant even though there's not as much travel before they lean on the collar. It would still take away some of the jarring vibrations. "We are undertaking more work to improve the oval collar. I think that's a really good step, a big improvement." These changes were incorporated into all the teams' existing chassis over the winter starting at the end of November. "I think there's only a few left to be done," Walker said. "We came up with a rotor system so each team initially provided one car to be modified. We didn't want one of the larger teams going in with six cars. That would have meant that a smaller team would have been waiting in line so we developed a team by team rotor system. "All the race cars have been done. We're going through spare cars now. There are between sixty and seventy cars out there. A local supplier has been doing all the work and it's been a nice orderly system which 'Rocket' (Kevin Blanch) has managed. It's been a good move I think, quite a successful change. "The work started in late November and early December. It's estimated to be about sixty percent improvement in side impact so hopefully that translates into safer racing. Dallara made the prototype in Italy and then sent a kit over and the boys here modified it. If you looked at the car you would hardly know it was on there. You wouldn't see the additions." Walker wants IndyCar to develop a more rigorous crash test than the current FIA method. "The FIA's method of measuring side impacts today tends to be more of a computer-calculated squeeze of the chassis rather than what we did in the old days which was to smash them and see how they stand up," Walker commented. "I favor the old crash test," he insists. "I think we need to take a concrete block and whack it and see how it stands up. So IndyCar is trying to find some more funding to get a chassis and go sledge test it. I think we need to do development of this kind. We've still got a few more years on this car and I think we need to look ahead. "Justin's crash, for example, really wasn't that severe. He would say it was, but the impact speed was not as bad as it could have been. There's always the possibility for a bigger crash and we have to take a proactive step in looking at that possibility by having a sledge impact test."  © LAT USA "We looked at the rear pod behind the rear wheel on the road courses," Walker related. "The speedway version is quite a robust section. It's stiff and it really hangs on fairly well. The intent of this pod is to delay an oncoming car hitting the car in front and being launched over the rear tires. You can whack this pod and the intent is that it delays or deflects the oncoming car somewhat so that it doesn't automatically ride over the rear wheel and start a launch sequence. That was the intent. "The road course configuration was a smaller and lighter constructed pod and most of the time it did a lot of good. There was a lot of nudging and banging into each other and the pod did its job. But when there was a serious, direct hit, it quite often fell short and collapsed and almost became part of the launching ramp for the oncoming wheel and tire. "So we did some work with Dallara on that. They looked at a lot of deflections and measurements of the lozenging of the pod and with some simple modifications it's measured at least equal to the speedway pod. "Some of the drivers voiced their opinion that the pod should be taken away but all the engineering data we've looked at about what the pod did convinced us to stay with it. The team owners also wanted to get rid of it, but we decided it was a useful safety item we wanted to stay with." Many IndyCar drivers have suggested the DW12 needs a power steering package of some type and a hydraulic steering damper will soon be tested. "The other area where there had been a lot of discussion was the amount of kick-back the drivers would get in their wrists from the steering wheel when they hit something or had a problem," Walker recounted. "The steering effort is pretty high with these cars so there was a lot of talk about going to power steering on the high-speed tracks. "That was not something we couldn't do, but it was problematic to do it quickly. Getting the power steering system into the car was a fairly big design job whether it was an electric or hydraulic system. We concluded that an electric system would be best for us but the engine manufacturers were concerned that the current alternators couldn't keep up with the demand. It would need another alternator design to put out a lot of juice to support a power steering system like that. "So the group of people involved in this work decided to try a steering damper that would still allow you to turn the wheel as normal but would catch any spikes in the steering load. Dallara and one of their suppliers came up with a steering damper that bolts onto the steering rack. "We're going through some tests with it right now to see that it works to improve that situation on the test bed. Once that testing is finished the steering damper will go onto a car and we'll get some guys to run it, trouble-shoot it and get as much opinion as we can. It's quite adjustable because we were concerned about it creating more steering drag. Dallara have done a good job to get it done at a reasonable price."  © LAT USA "It's certainly one of the challenges for IndyCar as a governing body," Walker remarked. "It's a bit like the FAA where they are constantly making recommendations about aircraft safety but all that costs money. Somebody has to pay for it. We've got a lot of ideas about things we want to improve over time and we can find people to do this work for us, but we've got to find the funding. "So we move in small, conservative steps because of the resources we have at our disposal. But I think it's part of the responsibility that the governing body should have. The car manufacturer can be part of that process but shouldn't be expected to take the lead in those developments. That's the sanctioning body's responsibility. But to do that we need to get some experts on board to point us in the right direction. "As we look towards the future, if we can start getting our fans back and getting our sponsorships up and the teams healthy, there should be a surcharge from within the sport to put money aside for the betterment of racing. We're not healthy enough to do that right now, but I hope that can happen in the future." Walker also explained the changes he's made for this year to IndyCar's race control and operations. "What I saw last year in race control in my first seven months on the job was really a surprise to me. The equipment we had really didn't provide enough view of the track and the quality of the equipment was poor. It was old and the replay was slow and the process for arriving at a decision I didn't think was consistent. "This year we have what I call the steward system. I looked at a lot of other series, Formula One included. Herbie (Blash) and Charlie (Whiting) were kind enough to let me into the F1 system at Austin last fall. I spent the weekend in and out of race control and they showed me everything. It was really very helpful to me and I decided we needed our own version of the same thing. "So we now have a three steward system. There's the race director, Beaux Barfield, who is one steward, and there are two other stewards in race control. If something happens, one or all of them can call for a review and a review is undertaken. The teams will be informed that the incident is under review and the two stewards who are not running the race at that time will look at the replays and all the data. "Beaux then joins them and the three of them look at it together and decide whether there's a penalty or not. It's a majority vote and if there's a penalty it will be linked to a rule that says what that penalty will be.  © LAT USA "Every incident is a little bit different but we've devised a chart or guideline of penalties that can be given. It could be a warning, it could be a stop and go, but the race director decides what the severity of that penalty may be and everyone--the teams, the fans, TV--will be informed. "The guidelines are pretty straightforward and will be consistently held to so it won't be somebody's interpretation. There's a time limit for the three stewards to complete their vote. If one of them is confused and doesn't know what to do the other two can vote. If there's a draw, or one steward says no, one says yes and one doesn't know, then the driver gets off Scot-free. "The race director, Beaux, is constant. The other two stewards will change on a rotating basis. They will cycle in and out every four races or so and they will change on different cycles so we always have consistency. Each steward will be rated after reach race and we will film and review everything that goes on in race control to see how everything works. As president of competition I have the right to remove any steward who I don't think is doing his job or following our guidelines. "I think it's going to work well. It's not the Formula One system. It's a little more hands-on and I think these changes will help us in the way we administer the sport. There are a lot of minor changes that are coming in the way we decide on full-course yellows or when we close or open the pits. The whole team here has been very busy through the off-season." Walker and I continue our discussion next week as he takes out his crystal ball to look into how IndyCar is likely to evolve in the future. |

|

Auto Racing ~ Gordon Kirby

Copyright ~ All Rights Reserved |