The Way It Is/ Bringing fuel injection to NASCARby Gordon Kirby |

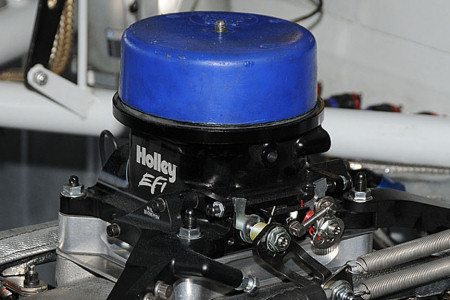

It's easy to joke about fuel injection coming to NASCAR fifty years after its arrival in many other forms of the sport and decades after EFI became common in passenger cars and trucks. But the arrival of EFI in this year's Sprint Cup series appears to be a healthy boost for NASCAR and has been managed well by its technical team. NASCAR's Sprint Cup fuel injection system comprises well-proven Bosch pumps, injectors and sensors plus an F1-based McLaren ECU and the package survived its debut at Daytona this past week with flying colors.

It's easy to joke about fuel injection coming to NASCAR fifty years after its arrival in many other forms of the sport and decades after EFI became common in passenger cars and trucks. But the arrival of EFI in this year's Sprint Cup series appears to be a healthy boost for NASCAR and has been managed well by its technical team. NASCAR's Sprint Cup fuel injection system comprises well-proven Bosch pumps, injectors and sensors plus an F1-based McLaren ECU and the package survived its debut at Daytona this past week with flying colors.

During the week at Daytona I discussed NASCAR's move to fuel injection with a selection of people in the Cup garage. Everyone stressed the vast pool of experience the suppliers, teams and manufacturers have been able to draw from for this transition. There was also a strong consensus that NASCAR's method in making the change happen was thorough and rigorous, and NASCAR's vice president of competition Robin Pemberton emphasized the point that before it could make the move NASCAR had to wait for each of the latest engines from Chevrolet, Ford, Dodge and Toyota to come on-line and reach stabilized specifications. "Fuel injection itself is not that difficult," commented Pemberton. "It's been a process that's been on our radar for probably five years. The reason it took so long is because we had to wait before all the architecture became similar between the four manufacturers' race engines. The hardest part was making sure we did all that ground work first. "Once that was established we could then go and interview and talk to different electronics providers about building a system for us. We started a process with companies that were both domestic and worldwide companies and all the time we were working with the teams. Many engine builders have a history with fuel injection, whether it's through endurance racing or other forms of racing, so it wasn't new to anybody."  © Paul Webb "We supply the fuel pumps and CV does all the machine work," said Wolfgang Hustedt, Bosch's longtime US racing manager. "We also supply 90 percent of the field with ignition coils and, like always, we supply alternators, starters and spark plugs to many of the teams." The injectors and 02 sensors are made in the United States. The injectors are made at Bosch's plant in Charleston, South Carolina, and the 02 sensors are made in Anderson, South Carolina. "The stuff we're supplying are all proven pieces," Hustedt noted. "There's no reason there should be any problems and I don't think they'll have any issues with the ECUs. "Normally in racing with electronics," Hustedt cautioned, "the biggest area of concern will be with the wiring harnesses." The McLaren ECU is similar to the unit used in F1 and IndyCar. McLaren's ECUs are produced in a partnership with Freescale, a large scale supplier of ECU and electronic bits to the automotive industry and a wide range of consumer products. Freescale has been a McLaren partner for ten years. McLaren Electronic Systems employs seven people at its base in Huntersville, NC and delivered more than 300 ECUs to the teams prior to Daytona. "We've been able to get everybody here to Daytona and we take great pride in that," commented Cameron Kerr, McLaren Electronics NASCAR program manager. "We were able to get everyone to the racetrack a week and a half before the race and we're going to get them to Phoenix and on from there all the way through the series. "We will continue to support the program fully as the teams get accustomed to and become comfortable with the system," Kerr added. "We will always have a minimum of three people at the track for each and every race. We have great people in the US and in England and there really isn't a challenge that we can't beat or make happen."  © Paul Webb "What we've seen so far is that the drivers notice minute things," Kerr said. "But they're not noticing big changes, which is the entire agenda of what we're trying to do. I think it's a tribute to the products that we make and the experience level that we have. People trust and know we can do the best job possible and put a critical part into a racing vehicle and know it will work." Robin Pemberton says NASCAR cast a wide net before settling on McLaren and Bosch as its primary EFI suppliers. "We went into it with a very open mind and we had a lot of great meetings," Pemberton related. "We started the process with about a dozen different companies, large and small. They all had different levels of success. They all had something different to offer us. There were many options out there but we did the due diligence and worked through the process and at the end we picked what we felt was right for the garage area. "McLaren and Bosch are two of the top companies in the world when it comes to motorsports and electronics, and the Freescale folks that are involved with McLaren have tremendous experience. It was important for us to deal with top-notch companies." Toyota Racing Development's president Lee White said that from the start Toyota has been an enthusiastic supporter of the move to EFI. Of course, TRD has plenty of fuel injection experience. "We went into it with a comfort level," White commented. "When they told us about the move we said, 'We were just getting carburetors figured out! Now we're going to have to drag out all this old stuff.' "We felt like we had a deep understanding of the challenges, but let's not forget that there are a lot of smart people in the NASCAR garage. The Ford guys with Roush-Yates motors didn't run one-two-three at this year's Daytona 24 hours with injected motors by luck. And the Chevy guys, Hendrick in particular, back when Toyota was just knocking on the door of IMSA prototype racing Rick Hendrick and the Chevy guys were running twin turbo V6 Corvette prototypes. So a lot of people in this garage have been around this stuff before. "If you look at names like Jeff Andrews at Hendrick and Nick Hayes at Childress. There are people Toyota competed against in Indy car racing and Formula One all the way through the garage. There are numerous F1 engineers through the garage working for every manufacturer and major teams. And again, to me, that's what's really fun to watch. The cross-pollination of the NASCAR garage with extremely well-educated people. It's a game-changer, not just for us but for the whole garage. "The best thing about this good first step in electronics," White added, "is the influx of people that are at a significantly different level than what we've been used to. The NASCAR teams have been used to having a tuner who would clean up the valves, change the springs and check the lag, work through materials and filters, change jets and set the timing with a light and so forth. Now, you still have to look after all those mechanical components but there's an engineering aspect to NASCAR cars now that we've never seen before. In my opinion, there's been an upgrade of the average intellect in the garage."  © Paul Webb "NASCAR has held weekly meetings and all the manufacturers and primary builders have participated," White remarked. "The manufacturers and Hendrick, Roush-Yates, Childress and the Penske guys have been right there with NASCAR every week talking about insulation issues, packaging issues, sensor issues--you name it. It's been very collaborative and productive right up there with the 2013 car which has probably been the most amazing collaboration we've ever seen. "Frankly, I think everyone used that as the impetus for the introduction of fuel injection. Everyone let the 2013 car take the lead. If there was an issue we needed to get it out on the table. That's the level of cooperation it looks like we've seen." Pemberton agrees, stressing it's about effectively controlling the sport and the cost of racing. "We do have good working relationships with all of our race teams and many of our vendors," Pemberton said. "That's where all the collaboration came in. It was about designing the system and the software and the checks and balances and having a system that we could use that we could govern and make sure we kept the costs in line and in check for the teams. If you just let it run wild it would be a science project that would never end and it wouldn't be good for the health of the sport." Lee White hopes the move to EFI is the first step on the path to NASCAR embracing more modern engine technology. "We have four engines in Cup racing all of which are expressly designed as NASCAR racing engines using an A30 carburetor," White observed. "Now we're retro-fitting a decade and a half old fuel injection system, which is a great step to getting where we'll be in say five years. "I'm hoping that perhaps NASCAR will start looking at direct injection and perhaps a more modern engine. But this is a good first step and it's all everyone could afford. No one could afford to throw away the basic architecture--the blocks, heads and cranks."  © Paul Webb "I think you will see us continue to move forward on a lot of avenues," Pemberton said. "As you know, it's still about how much burden you put on the teams. Anything that you can see out there, we've got our sights on it. The question is, when is the right time?" Pemberton agrees with White that the move to EFI is a step in the right direction for NASCAR. "I think one of the biggest gains has come not from the hardware or nuts and bolts of the system," he commented. "It's about our product relevance. We've put a big push and effort towards a lot of those things that we may have gotten away from or not kept in tune with. Not only that but the effort that went into putting the Nationwide car on the racetrack so it looked more like the showroom cars and getting the manufacturers where they had their identity and it wasn't just a decal anymore and that leads right over into the 2013 car. "It's been a real long process but it's been a vision of ours for many years. To do it safely and in a process because you don't want to drop all this stuff into the garage area all at one time. We knew where we were headed and we just had to stay the course in getting a lot of these things buttoned up. That's why it's taken years." Lee White said the biggest problem in adapting EFI systems to Cup cars was coping with the tremendous quantity of heat generated by a NASCAR car. "Making it run was a walk in the park," White said. "We had three engine vendors who had never touched an injected motor in their life. They came out and spent a couple of days at TRD. We shipped them a kit and all three were able to follow the diagrams, plug in the wires and had it on the dyno and running in less than a week. "The real issues for everyone have been the application in this car which is a very unfriendly environment for hundreds of wires and connectors when you look at the heat and the inertial loads and the vibration. The heat is a tremendous issue because the exhaust runs right through the car and you have to do everything you can do to try to keep the components cool. "Then there are the additional electronic requirements, primarily from the fuel pump. The system requires ten times the fuel pressure that a carburetor did. It's 75 psi rather than 7.5 psi, which is a tremendous increase in electrical supply. So everyone's had to upgrade their alternators. If you walk 'round the garage you'll see everyone is running cooling pipes to the alternator just to try to keep it alive. "The system appears to be very robust. McLaren and Freescale have been tremendous to work with in terms of any software issues, and believe me, we went through a bunch. We went up to Martinsville for a test day and it was in the 30s and guess what? Nobody had a cold start strategy. "So before we could turn a wheel the whole garage was in there working through the right strategy for a cold start. You couldn't just pump the gas like the drivers were used to and light her up. That didn't work anymore. All the little nuances you wouldn't dream about in terms of on track competition, just so you could light 'em up and drive out of the pits, has been an adventure.  © Paul Webb "NASCAR is still trying to figure out what to write down as the limitations because they don't know themselves. They're learning with all the rest of us as the onslaught comes." Pemberton stressed that telemetry is unlikely ever to be allowed during NASCAR race weekends. "We won't be there anytime soon by design," Pemberton declared. "They do it when they're testing and we'll save that for testing and run our races without any of that. We want the man and the machine. We want the teams and the human to do it. In our world, that's what makes us as healthy as we are. That's what keeps our owners healthy because at the end of the day the arms race doesn't help make racing better. It just helps you spend more money. "But we do enjoy this technology. It's been really a lot of fun. The teams are excited about it. It gives them an opportunity to tune on their motors like they've never been able to do. The power--everything will be better because of fuel injection. "There are different kinds of fuel pumps and fuel cells and sensors that the manufacturers and teams can use. They'll have to work on their own bugs based on what they have chosen or their particular sensors and other stuff. You can play with the settings a lot. "We know this is a very solid, basic fuel delivery system. That was and is our goal. In my opinion, our racing is so good we didn't want to screw that up. That was important. That being said there are tools in the toolbox that we are not using with this system for obvious reasons, and that is to keep the drivers driving and the crew chiefs working on their setup. We're walking a fine line here because we like the human element in our garages more than any other motorsport in the world. We rely on that. We feed off it. It's very important to us. "But that being said we think that as we grow and move forward there's plenty of room for growth in the departments we have to work with. When you introduce electronics into any system, it's endless. It's not any one thing. It's endless. As we move forward, it's making sure everyone has the same opportunity when you run an event. That's why we have to work so hard to keep it clean. "The first thing that a lot of people say is, 'Aren't you worried about traction control?' But the truth be known, that's not your biggest problem. Your biggest problem is the one you don't know about." NASCAR has trained some of its technical people to monitor the electronics for any rule-bending. "We are able to plug in at any time to make sure the software is what it is. That's how we run our garage area and people respect and expect that so everybody knows everyone is on a level playing field. We've got readers we plug in to check the code. We trained some of our existing people to do that. McLaren and the Freescale folks and Bosch have worked real hard to get all of our officials up to speed." Pemberton added that the penalty for messing with the electronics will be very serious. "Minor isn't even on the gauge," he commented. "It'll be a top of the line penalty. I expect all mechanics and engineers to push all they can but through the years you've seen what happens when we catch someone with a big engine or when someone messes with a restrictor plate or a spoiler or something that compromises the safety of the chassis. The reactions are big ones. So you can put that right on the big reaction gauge." NASCAR also hopes to provide its fans and TV audience with useful information gleaned from its new world. "We will do other things with the electronics," Pemberton said. "We will be able to advance the fans' experience. As we mine the data from those boxes and put it into the broadcast that will help the fan experience. That comes in parallel with just being relevant. We knew all along that this is an opportunity to do something to help our fans and that's as important to us as anything. Over the last few years we've been monitoring and paying attention to what the fans want with things like the 2013 car and the tandem-drafting, and we'll be continuing to do that." NASCAR is very aware that it needs to attract young fans as well as trying to reinspire some of its older, disaffected fans. They're trying to reach out on all fronts and the move to fuel injection and arrival of electronics is one of them. As always, time will tell what's right and what's wrong but you have to give NASCAR an A for effort. |

Auto Racing ~ Gordon Kirby Copyright 2012 ~ All Rights Reserved |