The Way It Is/ Why the Delta Wing will work

by Gordon Kirby As Ben Bowlby said in this space earlier this week many fans and racing industry people are filled with questions about the Delta Wing concept and how the car will work. To explore and explain some key questions about the Delta Wing I talked to Firestone's racing boss Al Speyer and his top engineers Page Mader and Dale Harrigle. I also asked legendary Formula One and Indy car designer John Barnard to read my columns about the Delta Wing and provide a critique of the concept.

As Ben Bowlby said in this space earlier this week many fans and racing industry people are filled with questions about the Delta Wing concept and how the car will work. To explore and explain some key questions about the Delta Wing I talked to Firestone's racing boss Al Speyer and his top engineers Page Mader and Dale Harrigle. I also asked legendary Formula One and Indy car designer John Barnard to read my columns about the Delta Wing and provide a critique of the concept.

Barnard designed McLaren's ground-breaking MP4 F1 cars from 1981-'86, Benetton's F1 machines from 1990-'92, Ferrari's F1 cars from 1993-'97 and Alain Prost's cars from 1999-2001. Prior to moving into F1 Barnard made his name in the late seventies and early eighties by designing the revolutionary Parnelli-Cosworth and Chaparral 2K Indy cars so he stands out as a rare man who designed many successful F1 and Indy cars.

First of all, Barnard made it clear that he's not a fan of spec cars and believes racing has fallen out of step with the need to help develop and promote greater efficiency and a genuine 'green' image in all areas from fuel consumption to aerodynamic drag, light weight and the development of hybrids, fuel cells and electric cars.

"As you've mentioned in some of your comments," Barnard began, "a lot of fans, I for one, don't particularly like the single make or spec formula series that seem to be growing in number. It is supposed to give close racing on a low budget but it always appears to end up with a couple of teams, usually with the bigger budgets, having the pick of the young drivers and tending to dominate the results.

"I do agree that racing should be helping to promote efficiency which is directly relatable to road cars. In fact, racing should have been doing this starting at least fifteen years ago. For me, the way to do this in Formula One is to have the fuel tank with a maximum volume that can be reduced year on year and be supplied with fuel from a regulation source so that fuel cooling and special fuels are avoided. This allows drivers and teams to play with their power output when and how they want, especially with a turbo engine, and means that every aspect of the car must be efficient, especially aero. It is also reasonably easy to check.

"All that being said, I would like to see more coming from power sources such as fuel cell electric and hybrid/electric, plus any other new developments--an electric motor in each wheel, for example. Think of the control possibilities and packaging options--wow! This would need the cooperation of some big manufacturers but there is nothing like racing to inject some pace into development.

© LAT USA

Regarding the Delta Wing, Barnard's first question was about the quantity of downforce it will generate.

"When I first saw the pictures of the car I thought it was a land speed record car because it must have a very low drag factor," Barnard remarked. "So I would be surprised and interested to know what downforce it will generate. The plan area appears not to be huge and with no skirts or wings I'm a bit skeptical on its downforce potential. I'm not really turning into a negative old man, but novel thinkers must expect constructive criticism. I know from experience."

In fact, if Barnard were to see the Delta Wing in real life he would realize that it has a lot of plan area--the total amount of bodywork area viewed from above or below.

"I'm sure the photos are deceptive," Ben Bowlby points out. "We have an enormous plan area. Because we've covered the rear wheels and the body is right to the outside width and the tires are narrower we've ended up with a far larger underbody than we have with today's cars. Plus, by being half the weight we only need half as much downforce to get the same performance. So we don't have to get as greedy. If the car weighed twice as much we'd have to make twice as much downforce and that would start to be a challenge."

Bowlby also makes the point that the wicker or Gurney flap at the Delta Wing's tail not only has a big effect on overall downforce but will also help Delta Wing-type cars race better because their wakes will be much less turbulent.

"If we increase the height of the wicker we obviously add drag," Bowlby noted. "But we massively increase downforce as well and the device is far less sensitive than a heavily optimised airfoil section. When the air flow is on the cusp of detaching you've got as much optimization as you can possibly get out of the air. It becomes very turbulent and flow angle sensitive and that's one of the things that has probably hurt the racing car more than anything as we've got better and better and better at extracting the maximum from the regulation package."

As an aside, it's instructive to see the Gurney flap, invented almost forty years ago by one of America's greatest racing men, is as effective on the Delta Wing as it's been on so many race cars over the years.

"Any race car engineer who has experienced many types of racing cars and found the Gurney flap to be his friend knows it is simply one of the most effective devices anyone has invented," Bowlby remarks.

© LAT USA

"I do love a bit of lateral thinking and the Delta Wing concept is certainly eye-catching," Barnard commented. "But most of the statements made in your article can be implimented on a car with the front wheels in a normal position. I have a problem believing that this configuration will have the cornering capability of a regular four-wheel layout. I guess Ben wants to make the balancing act for the driver more obvious. But I would be surprised if the fans will be impressed, especially on road circuits at slow corners."

But Bowlby has explained to many people that the Delta Wing will turn superbly because of its lightly-loaded front end and distinctly rearward weight distribution and center of gravity.

"First of all," Bowlby relates, "the car has a very narrow front track and very wide rear track and the width of the car is not very different from today's car. The key element in the car's stability is that in our case the center of gravity is much rearwards between the widely-spaced wheels. But it's also part of the overall characteristics of the car that by having the weight rearwards we've unloaded the demands on the front tires. The front tires are only having to manage a very small percentage of the mass of the vehicle and they have a large leverage on the center of gravity.

"Working with Firestone we have optimized the capacity of the front tires to match the mass that they have to handle. So they saturate in terms of their lateral capacity at the same point that the rear tires saturate. Everything is in balance. It's a very good reminder that a car is a series of elements that have to work in harmony. If the mass, the tire capacity and the aerodynamics are at a cross curve you have an ill-handling machine. If they are all in tune, then everything is balanced.

"We believe our concept with the narrow front track absolutely works," Bowlby adds. "All of our simulations demonstrate to us very clearly that we will have a good, well-handling car that achieves all of the things we're looking for."

Firestone's Delta Wing tires were designed and developed by Dale Harrigle who has been with Firestone since 1992. Harrigle has worked in Firestone's racing division since September of 1994. Firestone's racing boss Al Speyer recalls that he brought Harrigle into the first meeting he had with Bowlby to discuss the Delta Wing project.

"When Delta Wing first came to us they wanted to show it to us and discuss the whole concept because it was unique and different," Speyer said. "But about ten minutes into the presentation I said, 'We've got to stop. I want to get an engineer to come in and go back through the process.'

"So Dale came into the meeting and Delta Wing had some concerns about tires, whether it could be done or whether it was feasible. But right from the get-go Dale didn't have many concerns. It being sustantially lighter was some concern, but it wasn't like, 'Oh, we can't do that."

Commented Page Mader, Firestone's director of racing tire development: "Dale did a great job, as always."

Harrigle expanded from Firestone's perspective on Bowlby's comments about the Delta Wing's theoretical responsiveness.

© Chip Ganassi Racing Teams Inc

"From their simulations we looked at what loads the tires needed to carry. We really focused on load. We worked with Ben and his team to try and decide how much lateral force a four-inch wide tire can generate and have the car stay in balance. All the simulations point to the fact that the car is going to be balanced and should be a well-behaved car that is easy to drive. We worked from the perspective of grip front to rear and load-carrying capacity front to rear.

"With the Delta Wing the front of the car is very light weight," Harrigle added. "There's not much structure to the front of the car so the front tires can be smaller. You don't have the demands placed on them that our current tires do."

Harrigle says the Delta Wing's ability to lithely negotiate a tight turn like the Long Beach hairpin will be an excellent promotional point for Firestone.

"It's a great thing for us because peoples' perception is that the front tire can't do the job," Harrigle remarked. "So it's going to be a strong point for us if we can build this tiny little front tire that can do that job and do it well."

Harrigle has no doubts that both the Delta Wing and its Firestone tires will be up to the task. He takes added confidence from the work put into the project by veteran racing engineer Jim Hamilton.

"Jim has been very involved with the simulations and in my personal opinion Jim's probably one of the smartest people I've ever met," Harrigle declared. "We believe the tire can do the job to generate the forces required to get the car around the race track."

Nevertheless, like many people, John Barnard's first inspection from afar led him to believe the Delta Wing will require a wider front track and some type of front wings to act as trim tabs if nothing else.

"It seems to me that the first thing to happen, should the Delta Wing actually get on the track, is it will grow a pair of small front wings for balance adjustment," Barnard said. "If you start to apply steerable closed front wheel fairings attached to the wheels together with a reduction in wings and increase in underbody downforce, then a standard wheel configuration car would become more efficient and more overtaking-friendly. My gut feeling is that if you pulled the front wheels out to a wide track position and did some imaginative and clever aero design around the wheels it would be a better race car, but still innovative and eye-catching."

© Chip Ganassi Racing Teams Inc

"As soon as you start widening the front tires the concept runs away from us," Bowlby observes. "One of the things that happens when you move the tires more widely apart is there is implicit load-transfer capability between the inside and the outside tires. The greater the distance between them, the more potential for taking the load entirely off one and putting it on the other tire. If you do that, in order to avoid a blow-out, the capacity of the tire has to increase.

"This is a spiral. As soon as you increase the capacity of the tire in order to balance the car in the entry phase of the corner when all the weight is being transferred to the front of the car during braking, your reaction has to be to move the weight forward and you would then have an unbalanced car that's over-tired at the front. And once you move the weight forward then you have to move the aero forward so you have a car that is much more like we have today.

"It's a subtle balance between a concept working and a concept reverting to a former concept. As soon as we go away from the narrow front track principles, the weight has to go forward and the car becomes a conventional car. We would also have the increased drag from the front tires to contend with."

Bowlby adds that he's deeply aware of the role compromise plays in the design of any racing car.

"The whole of any race car is a compromise and the winning race car in my opinion is the best compromise," he remarks. "I don't subscribe to the theory that a race car can be designed without compromise. I think that's completely inaccurate. The best cars are the best compromise."

Bowlby emphasizes that the Delta Wing will generate most of its downforce through the underbody. He and his engineering team have designed the car to run without front wings to be more effective in general and to enable it to run more closely behind other cars and be able to pass more readily.

"The conventional wisdom is that you need some method of adjusting the aerodynamic balance," Bowlby relates. "The difficulty is that traditional viewpoint has created cars that don't race well in their own wake. So we had to be disciplined after the things we discovered in CFD and be cautious to avoid any form of aerodynamic device that was far forward in the car or ahead of the front wheels because it was the first thing to lose performance in traffic.

"To tune the aero balance we will probably have some leading edge, curvature-changing inserts that can manipulate the center of pressure. But in gross terms the aero balance of the car puts somewhere around 77 percent on the rear, and we will produce the majority of the downforce form the underbody and the rear of the car. We will use the mechanical solution of the torque vectoring or torque steer of the 'diff' to alter the balance of the car which will be completely unaffected by the proximity of another car."

Another interesting aspect of the Delta Wing's front suspension layout is that it operates without any push or pull rods. The shock absorbers are located simply in classic fashion linked directly to the wishbone at a traditional, fairly steep angle which reduces the overall mass of the front suspension and permits more direct operation of the shocks.

"Removing a pushrod, a rocker and a rocker pin and simply putting a shock between the lower wishbone and the chassis at a nice steep angle is all possible with the layout of the car," Bowlby points out. "That gives you a good load to motion ratio and a reduced number of parts. It makes a very elegant design.

"The biggest advantage is the simplicity, light weight and lack of complexity of friction and load paths. To meet our weight and our cost targets we have to reduce the number of components. We also had to make those components optimized from a mechanical and a mass standpoint."

Firestone's Dale Harrigle agrees with Bowlby but says it will take actual track testing to sort the correct details of the tires.

© LAT USA

And too, the Delta Wing's wishbones or A-arms are simpler, cheaper and more effective than those on today's conventional open-wheel cars.

"Because our wishbones are shrouded by bodywork they don't need to be aerodynamic sections to reduce drag," Bowlby explains. "All of today's open wheel cars employ aerodynamically-shaped wishbones to reduce drag, which make them poor solutions from a structural standpoint. When you build aero-shaped wishbones they get heavy and are difficult to manufacture.

"We have very simple wishbones which are beautifully elegant and optimized for their structural capability which makes them light and inexpensive to manufacture. They are very thin wall, round tubes. It's a really lovely solution. They can also be machined from a single piece of aluminum billet with an I-section if you prefer. Because they don't have any aerodynamic influence they are optimized from a mechanical standpoint."

Dale Harrigle says Firestone would prefer slightly larger tires all-round but the company is happy with the current solution.

"With Ben's focus on light weight and less drag he would like the tires to be as small as physically possible," Harrigle observed. "But we would like them to be a little bit larger because a larger tire has more air volume and more load-carrying capacity and a little more grip.

"So there was some give and take over a couple of months where Ben proposed a tire size and we would put through our models and ideas of what a given-sized tire can carry from a load standpoint. We would then propose a size back. We iterated on the size that was decided on and it was definitely a joint effort betwen Ben and his design team and our design team at Bridgestone/Firestone."

Firestone's racing boss Al Speyer explained the company's preference for producing the safest possible tires.

"Load-carrying capacity of the tire is very dependent on how much air is inside the tire," Speyer related. "The extreme is a bicycle tire with a very small amount of air that doesn't carry much load. The other end is a huge earth mover that has a lot of air in it and carries a huge load.

"In racing, particularly on the ovals, we want to make sure the tires will adequately carry the load that's being put on them with all the downforce that's put in there and the forces caused from the banking and the turn radius at 225 mph."

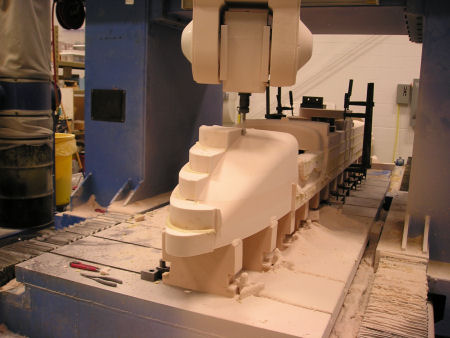

Dale Harrigle could not have been more satisfied with the Delta Wing's first wind tunnel test.

"The wind tunnel test was done on actual race front tires," Harigle said. "They were not display tires. They are reduced scale copies of our current superspeedway front tire. We were quite happy with the wind tunnel tests. We had done indoor testing prior to releasing the tires to Delta Wing so we knew they were going to be able to run the speeds and the loads that were required. Ben was very happy with the tires and we were quite happy with the performance of the tires in the tunnel."

Al Speyer declared complete confidence in Firestone's Delta Wing tires: "The specifics of the test are proprietary to Bridgestone/Firestone but we can say the test data shows the tires will be up to job."

Page Mader described the testing process Firestone puts all its race tires through.

"The tires that we tested in the tunnel went through the whole process of design, testing and setup that we've followed over the past sixteen or seventeen years," Mader related. "When we started in racing we tested lots of tires for these parameters. If they performed fine through all those tests we were confident they would run fine at the track and we have that test-proven confidence with the Delta Wing tires."

Dale Harrigle adds that Firestone's thorough lab and dynamic testing programs have been refined over the years and confirmed that the tires will perform impeccably in real life.

"We have an indoor drum that's capable of running the speeds that these cars are running," Harrigle explained. "We are capable of duplicating the loads and the cambers and the speeds that we run. Based on industry standards we have test data that shows a good history that if the tire will survive this test it will survive on the racetrack. And we completed all that testing with the Delta Wing tires."

In fact, the rear tires for the Delta Wing are Indy Lights front tires. But the four-inch wide front tires are entirely new.

"We haven't done race tires of this size since the late eighties of early nineties for Formula Vee," Harrigle observed. "It was interesting because the front tire especially was so much different than what we're currently building.

"For any new-sized tire the largest single thing for us is to build a new mold," Harrigle added. "Each tire size requires a dedicated mold. So we brought in a new mold for both the front and rear Delta Wing tires. Creating that new mold size and shape was actually our largest single investment."

At this stage Firestone has built fewer than ten fronts and ten rear tires for the Delta Wing.

"We've built a small number because we cut the tires apart and analyse them to make sure all the components are correct and where they should be," Harrigle commented. "The front tires worked fine. Everything worked fine. So we were able to release those for the wind tunnel test. The rear tires were not as good but we're going to rebuild some rears in a month or two and correct what we found wrong."

Firestone's executive director of racing Al Speyer emphasized that the company has no favorites in the contest for who will design and build the 2012 Indy car.

"Firestone Racing is impartial in the selection process for the next generation Indy car," Speyer said. "I am very confident that we can design, develop, manufacture, deliver and service Firestone Firehawk tires better than anyone else for whatever the next generation Indy car or cars may be.

"We've provided all the other designs with whatever information they want. We've got some agreements with them, but all the other designs are not a change for us. They either plan to use exactly the same tires we have currently, or maybe just a little smaller, but there's no great departure from where we are. So all the other designs are easy for us to adjust to."

Speyer says Firestone enjoyed tremendous exposure from debuting the Delta Wing on its stand at the Chicago Auto Show in February.

"It was very interesting when the Delta Wing concept was presented to our top management, including our marketing people," Speyer commented. "There were different opinions from everybody involved. But the marketing group in particular thought it was such a striking departure from the current car that they asked me if we could have it available for our booth in the Chicago Auto Show. They thought it would bring in a lot of attention. So I called IndyCar and they said they thought it would be a great idea.

"It was the marketing department not the racing division who wanted it there and it was very successful from a marketing standpoint. It got us a lot of exposure both at the Chicago Auto Show and internationally with the number of photographs taken of the car on our tires. We got a lot of exposure out of it."

Speyer added that Firestone's IndyCar program has been a great success.

"The decision to withdraw from Formula One doesn't have any impact on what we're doing here in the United States. The Indy car racing program has been such a strong impact for the Firestone brand, particularly given our heritage and history at the Speedway. It's had a dramatic impact on sales so it's something that's very solid for us."

In assessing the Delta Wing I also asked my old friend Bobby Unser for his critique of the car. Three-time Indy 500 winner Unser was a classic, seat-of-the-pants test and development driver long before the days of computers and data-gathering. Bobby stands with Mario Andretti, Dan Gurney, A.J. Foyt and Parnelli Jones as one of the most effective and relentless test and development drivers.

One day in Indianapolis last month Ben Bowlby gave Bobby a thorough tour of the Delta Wing and after Bobby read my column from two weeks go he replied with remarkably little ciricism. I was amazed that Bobby's only serious doubt concerned the Delta Wng's theoretical data and its electronic diff.

"I have a problem with a lot of the data that does not exist," Unser remarked. "Sooner or later, if it's going to go forward, it will have to turn and I don't know for sure that a computer-driven transmission will be the answer. Many problems will be there. So best to wait and see if this really will be the best thing for the racing world."

When that's the only criticism Bobby Unser has about the Delta Wing you know that Ben Bowlby is onto some big breakthroughs for a sport that is thirsting for them.

Finally, to properly cope with its new formula in 2012 and beyond IndyCar must seriously upgrade its technical department. Randy Bernard must reach out and hire a world-class engineer like John Barnard as a consultant to write the rules and help IndyCar maintain a competitive balance between manufacturers as the series develops in the way most of us hope.

An accomplished racing engineer like Barnard will be urgently needed to work through the devilish details of the rules and provide the sport with the ongoing technical leadership required. Other potential choices include former Brabham F1 designer Gordon Murray, former Eagle Indy car and GTP designer John Ward, or former Lola and Reynard man Bruce Ashmore of the BAT group, all extremely well-qualified and worth talking to.

*Correction: I've created some confusion about the 'Global Racing Engine' and must make clear that the proposed Formula One engine for 2013 is NOT a 'GRE'. The proposed 1.5 liter turbo four-cylinder F1 engine is a stressed, structural member and not a stock-block-based, unstressed engine as the 1.6 liter 'GRE' is intended. The F1 four-cylinder turbo is supposed to make 550 bhp versus 300 or so for the 'GRE' and will turn considerably more rpm than the low-revving (around 7,000 rpm) 'GRE'. But the roughly similar F1 engine should provide the basis for development of the 'GRE', which will be introduced by the FIA in the coming years into Le Mans-type sports car racing, the World Rally Championship, the World Touring Car Championship and hopefully IndyCar too.

Auto Racing ~ Gordon Kirby

Copyright 2010 ~ All Rights Reserved

Copyright 2010 ~ All Rights Reserved

Top of Page