The Way It Is/ Exploring how Metalore manufactures its fine racing products/ Part Two

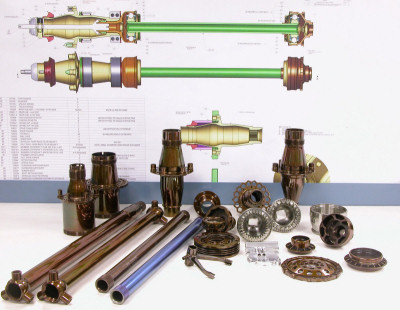

by Gordon Kirby One of LA-based Metalore's biggest contracts in motor racing is churning out all the driveline and wheel hub components for Champ Cars' Panoz DP01 spec car. Given his racing roots with the Vel's Parnelli Jones team, Metalore's boss Kenny Hill has great affection for Indy and Champ car racing. So he's delighted to continue as a major supplier to Champ Car even though he can't convince himself to believe in spec car racing.

One of LA-based Metalore's biggest contracts in motor racing is churning out all the driveline and wheel hub components for Champ Cars' Panoz DP01 spec car. Given his racing roots with the Vel's Parnelli Jones team, Metalore's boss Kenny Hill has great affection for Indy and Champ car racing. So he's delighted to continue as a major supplier to Champ Car even though he can't convince himself to believe in spec car racing.

"We're doing the whole Champ Car thing," Hill said. "We're the supplier for all the drive system on the car and I assume that will go for the next two or three or four years."

But Hill objects in his soul to the spec car concept and can't stop himself airing his opinion on the subject. "On the one hand, a spec car is kind of fun for me in a sense," he remarked. "But I'm afraid I'm absolutely adamant about the fact that it's not going to go anywhere. I think everybody was always rooting at the Speedway for the V-6 Buick, or Pontiac, that was never going to make it. Or the Novi, or the turbine, because they were different. All these things, like Barnard's Chaparral ground-effect car, were all invented pieces and people loved it.

"Something new is always good," Hill continued. "That's been the lifeblood of racing and I think this whole idea of a spec series is absolutely, diabolically dead wrong. It should be a mix of different cars and different engines. I really believe that's what people want to see."

Hill and Metalore were among the members of the motorsports community who found themselves pushed out of the Indy 500 after Tony George created the IRL in 1996. Metalore was invited to supply its high-quality driveline components to the IRL but Hill determined he couldn't handle such a large additional volume of work.

"We were asked to build all four corners of the new IRL car they were going to build," Hill recounted. "I thought about it and we were pretty busy at the time. I sent a long letter explaining that we were in the process of moving to a larger building and our capacities were stretched pretty thin. I explained why there was no way Metalore could build that much hardware. We just didn't have the capacity to build that much stuff. I tried to be honest about it, but until three years ago they never talked to me again."

© LAT USA

But after Champ Car decided it was going to a new spec car in 2007, Metalore's Champ Car business essentially evaporated. "When CART became Champ Car everything continued okay for a few years but when they announced a couple of years ago that they were going to do this spec car, then all our business just died on the vine. The teams would buy one part at a time because they were all trying to cut down to a zero-zero balance so they had no parts left at the end of last year. They wanted their cupboards to be bare when they finished the season. That was a major upheavel for all their suppliers because the teams weren't buying any spares, just stretching everything and patching things up to last to the end of last year.

"But now it's a new ballgame and I'm enthusiastic about it," Hill added. "The teams are buying hardware and parts and that's not happened for three or four years."

Hill has some interesting observations about the challenges posed for the racing industry by the very dissimilar worlds of manufacturer-dominated F1 and Champ Car's spec car formula. "Now that the car companies own almost every F1 team they've become something different," Hill remarked. "Today, they want to remove and replace everything on Monday morning. They want to throw it all away and put on new parts. I suspect that's because the races are financially so important that they can't jeopardize anything. Win, lose or draw, the teams want to make the manufacturer responsible for every brand new thing that goes on the car."

Hill believes today's manufacturer-driven version of F1 has become inefficient and incorrect. "From my knowledge and experience, the best part you have in your inventory to put on the car for tomorrow's Indy 500 is one that's been run so the manufacturing flaws are out of it. It's been run for maybe fifty miles so we know it's a good part without any manufacturing flaws. It's not a brand new part. It's ninety-nine-point-nine percent new and that's the best part to go in the car for the most important race. Yet these guys have lost sight of that and become dependent on procedures and quality control, more paperwork, more data and more people."

According to Hill, F1's biggest manufacturer teams have clogged racing's cottage industry by ordering huge numbers of components to satisfy the latest big-team philosophy of always running new parts at any cost.

"One of the things that's happened is that many new parts have been ordered in massive quantities, like a hundred instead of six or ten," Hill said. "In some cases, there are suppliers who have been absolutely buried with backlog to where they can't perform, and eighty percent of this stuff is going to be thrown in the trash anyway! So all of a sudden the infrastructure was absolutely deluged with business but had nowhere to turn to get enough people cultivated fast enough to produce that much hardware. That is essentially what's happened to F1."

Hill points out that the large volume of components required by a field full of the same spec car means Champ Car is fighting a similar plague. "When you do a spec series it's not too far removed from what's going on in F1," he commented. "The overburdened part of Champ Car this past year is that one company, the low bidder, was gearing up to build thirty or forty cars, and then the radiator guy and the differential guy and everyone else were assigned to do forty sets of stuff. And not one of them, including me, could perform as far as trying to stay on top of it."

Hill says the problem wouldn't exist if there were two or three competing chassis manufacturers, like there were for most of CART's twenty-five years. "If the cars were Lolas and Reynards and Penskes--whatever, but a number of different chassis--everybody would be busy," Hill observed. "But they wouldn't be busy building forty sets, which is one hundred and sixty hubs in our case, all being demanded simultaneously.

"And if the guy who builds one little thing falls down, whether its a cotter pin or a little screw, the whole series collapses. In my mind, this whole spec series makes no sense whatsoever."

Hill also has some interesting observations about the federal government's procurement system with which he has considerable experience. Times have changed and these days the government is looking to racing people to produce the equipment required for today's wars.

© Metalore

"I grew up in the aerospace industry working on making space shuttle spares and the Gemini and Apollo projects. So it was government, government, everywhere, with NASA, the Navy, or the Air Force. Everything technically has got to be right on the button and on the paper trail. If a government official or Air Force colonel walked in and didn't like it, you weren't going to get your payroll done."

Many racing or former racing shops are turning-out secret products to help the war effort. "Here's the oxymoron I need to be clear about," Hill went on. "The federal government has relinquished so many things from their standards. Today, they shop for fasteners and things like this on the internet! They go to the low bidder.

"So the federal goverment has gone full circle and come back to race car teams and shops and said, you guys are pretty quick on your feet and build some pretty good stuff. The feds have come and asked some race shops to do some research and build some stuff for them. It's come around full circle. The feds have gone to these people--who are all free thinkers instead of spec car builders--and asked them to build some stuff, like a dune buggy that will run across the desert and hold a 50 mm gun.

"It's a strange thing that has turned hands," Hill added. "If you look at a 1960 Indy car it's got military fittings and standards and heli-arc welding, all done to a military standard."

Hill points out that most modern race car technology was discovered and developed in the aerospace industry. "If you look at a race car today, it might as well be an F-111 fighter aircraft that doesn't fly. It has Army-Navy fittings and braided lines and standards. All that stuff came from aerospace. Nothing came from the automotive side, including carbon which John Barnard found at the Hercules Company in Salt Lake City. It all came from the air force, military and government."

Metalore moved into its current building twelve years ago but the time is coming for another move. "I thought we would never get out of this building and we're about to outgrow this place," Hill said. "I guess I've had a slow month but I can't remember when. It must have been six or seven years ago. For a machine company to be busy fifty-two weeks a year, two shifts, six days, is absolutely unheard of. But we manage to stay busy."

The company employs twenty-eight people working two shifts, six days a week. "I'm not smart enough to have forty people because I had forty at one time and I could never figure out what they were doing," Hill remarked. "Trying to hire good people in today's world is painful. But it's always been painful trying to do something three times better than anybody else does. It's just a lot of work. It takes a mindset and it's not easy to find people who have that.

"If we get a really good, cracker-jack guy in here, it'll take another year and half before we can get him settled down before he can finally make a part that's presentable to our standards. I'm not being facetious about it. That's what it is. And that's why I want to keep it around the same number of employees."

As John Barnard said last week at the beginning of this opus, Hill has always been committed to having the best possible manufacturing equipment at Metalore. "In the last two and a half years I bought more equipment than I bought in twenty years," Hill grinned. "I bought two, new diamond-cutting machines which are high-speed, 40,000 rpm machines with linear motors. No rotating motors anymore. They have ceramic tables, and are super fast. They can pull eight or nine gs while accelerating. We hard-cut a lot of stuff with these machines.

"We bought two big, new shaft-turning machines with centers and twin turrets on them. They're a quarter million bucks apiece. Four years ago we bought a Sip Hauser jig grinder. It has brand new electronic controls and is worth probably half a million dollars. We also have a five-axis mill that runs twenty hours a day."

Hill marvels at the quality of the pieces produced by today's superb machinery. "I've been in this business my whole life and the accuracy and the finishes coming off these new tools and cutting geometry is wonderful. It's very, very expensive, but it is very, very good."

The cost of raw materials has skyrocketed in recent years, but Hill says the increase in the quality of the finished product makes good business sense. "Some of material is now approaching not under $50 a pound for steel and about the same for titanium," Hill related. "Three years ago titanium was $16 a pound and steel was $5, but we're still in the business of trying to sell price per mile. If we can build a driveshaft that'll run 7,000 race miles, it's cost-effective to run 7,000 miles and non-cost-effective to pull it out after 2,500 miles because you think it's tired.

"So we're having to stretch things farther and we're trying to get the teams to stretch things farther because the longevity is there. The materials are that much better.

"It's all cost-effective," he added. "If it doesn't work then it doesn't make sense for us to build it. I don't have any interest in making something that's cheaper. I have an interest in making something that's as good as it can be for the money they are willing to spend. That's what we stand by."

At an age when most people would be considering retirement, Hill remains as enthusiastic as ever about his profession. "If somebody asked me in 1985 to build the driveshafts we're building for a Formula 1 car today, I would have thought you were crazy," he grinned. "We're doing some development work with a lot of new materials and new processes. So we're on the threshold of technology and it's great fun."

The passion of Metalore's owner and motivator is there for all the world to see in its fine products. They are what racing's pursuit for excellence is all about.

And with that, I bid you adieu for this year. I hope you enjoy the upcoming holiday season and are ready for the challenges of the new year. Look for my first column of 2008 here on January 7th.

Auto Racing ~ Gordon Kirby

Copyright 2007 ~ All Rights Reserved

Copyright 2007 ~ All Rights Reserved

Top of Page