The Way It Is/ Lola's IRL sales pitch

by Gordon Kirby Lola Cars is one of the world's most successful racing car manufacturers and the winners of 183 Indy or Champ car races over forty years from 1966-2006. Founded in 1957 by Eric Broadley Lola has built more than 4,000 cars and won races in almost every major category from Formula One, Indy cars, Can-Am and long-distance sports car racing to many smaller classes like Formula Ford, Atlantic and Sports 2000. Today, Lola is owned by Martin Birrane who bought the bankrupt company from Broadley in 1998 and has developed Lola into a broad-based, hi-tech manufacturing operation building not only racing cars but also composite components for the automotive, aerospace, defense and wind turbine industries.

Lola Cars is one of the world's most successful racing car manufacturers and the winners of 183 Indy or Champ car races over forty years from 1966-2006. Founded in 1957 by Eric Broadley Lola has built more than 4,000 cars and won races in almost every major category from Formula One, Indy cars, Can-Am and long-distance sports car racing to many smaller classes like Formula Ford, Atlantic and Sports 2000. Today, Lola is owned by Martin Birrane who bought the bankrupt company from Broadley in 1998 and has developed Lola into a broad-based, hi-tech manufacturing operation building not only racing cars but also composite components for the automotive, aerospace, defense and wind turbine industries.

The Lola Group employs 220 people, including 85 engineers, at its headquarters in Huntingdon, Cambridgeshire in the UK. Irishman Birrane is Lola Group's chairman. A veteran racer, Birrane is a London-based property developer in the UK, Ireland and Spain who has invested heavily over the past twelve years in rebuilding and modernizing Lola's infrastructure.

Robin Brundle--brother of former F1 racer Martin--is Lola's managing director. Brundle was at Long Beach last month with Lola's US manager Steve Charsley to pitch Randy Bernard and the IRL on its plans to build an Indy car for the new 2012 formula. Brundle and Charsley briefed me on Lola's capabilities and the company's concept for a new Indy car.

"The technical center and design center at Lola is all under one roof along with the assembly and manufacturing plant," Brundle told me. "We've got five autoclaves and five axis machines and all the tooling you can imagine. We've got the wind tunnel and a seven-post shaker rig.

© Lolo Cars

"We also build Talisman mini-submarines. They are designed for the British government to do surveillance for terrorist threats in the Thames River and so forth. They are a Lola-designed and built product with three little missiles on it so it can go out and do mine-sweeping. So we have the capability to work with BAE and governments around the world and it's all leading edge technology."

Over the past five years Lola has also manufactured compound curve composite body panels for the Mercedes-Benz SLR.

"We were selected for this job because of our very strong ability to understand the resin infusion process and to understand the demands of Mercedes-Benz on quality and quality of refit," Brundle commented. "This is a particularly complicated way to use carbon. This again is an area where Lola has stood-out well. To me, that's a carry-over from the motorsport environment. If you look back to when Lola was in Champ Car we had a particularly strong record of parts arriving and being abe to be fitted to the car without rejigging or grinding them."

© Lola Cars

"We work with companies such as 'Quiet Revolution' to manufacture rooftop-mounted wind turbines," Brundle said. "We're also manufacturing the blades for the large wind farms you see out at sea and on tops of mountain ranges. We also do little tiny ones. We do what I call a lawnmower blade that can sit on top of a building."

Chairman Birrane has also pushed Lola to become more involved in helping the restoration and maintenance of historic racing Lolas, including the iconic T-70 Can-Am and long-distance sports cars from the sixties.

"Lola is picking up the heritage side significantly now," Brundle remarked. "It's something that we've been a little passive on over a period of a time, but we're becoming very active. We've got the blueprints and the tooling but all these cars that are thirty or fifty years old are not exactly the same. We've got a whole network of people both in the States and Europe that are able to manufacture components from patterns and compare them with blueprints so they can have the Lola stamp on them. It's not an exact science. We have to work very closely with the owners and the engineers but it's a very satisfying and useful part of our business."

In recent years Lola has built half a dozen LMP1 and P2 sports cars per year. Lola has also built more than seventy 'World Junior Cars' based on the company's recently successful Formula 3 car. Twenty-five of these cars were bought by the Jim Russell school for its series run at Infineon Raceway.

Currently, Steve Charsley and Lola North America are based in Mooresville, NC. Charsley and some of Lola's engineers have been talking with IRL officials about the new 2012 IndCar formula for much of the past year.

"We started with an initial meeting with the IRL last year which went to a more serious meeting at Homestead in 2009," Charlsey said. "Our engineers came over and met with the IRL and started putting forward what our ideas were. We had a questionaire of about a hundred questions we got answers to. They started with: Could we get in and what are the opportunities? We got those answers and we decided we did want to and we came up with our idea of what the solution was without any influence from what other people were doing. The IRL told us they wanted a car with a turbo motor with 550 hp for the speedways and 700 plus on road courses."

© Lola Cars

"The IRL want to see increased safety," he began. "Number one, the current car is ten years old in design already. And that's no fault of Dallara. That's just the way things have developed. It's ten years later and whoever designs and builds a car now it's going to be better than it is currently. We've learned a lot in that time.

"The next item is affordability. Because of the economic climate we have to work to a budget and that means it still has to be a single-make series. We would love to have two or three manufacturers out there but that would escalate costs. It would be great for competition and great for us. We'd love it, but if they want to keep to a budget it's not going to work. But maybe it's just a band-aid for the next three to four years when times change and we can go back to the old ways. We have to aspire to get it to where it was once again.

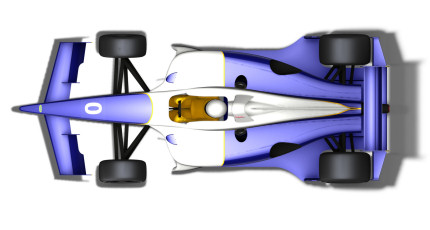

"The IRL are looking at ways to increase fan interest and entice the audience. That's a multiple of things including looks and competition. Varying the looks is one of the mainstays of our concept. We have wheel protection at the front and back and side-to-side in a stylish way we think all the way through. Our car has several design features from front to back which help make the car safer and lighter. This car will weigh 1,380 pounds, 200 pounds plus lighter than the current car.

"We're going back to the good old-fashioned underbody for stability," Charsley addded. "We'll work with underbody blockers for some tracks. So you get a complete aero package with blockers and a double plane or single plane front wing. All that comes as a package with the car. Our cars will be delivered complete with aero packages for different tracks. There are no extras. When you buy the car you've got everything but the engine."

Lola's proposal includes a pitch to build both Indy and Lights cars sharing a common chassis.

"We see the Indy Lights series as being of paramount importance to the IndyCar series," Charsley observed. "The Lights cars are now going to top speeds of close to 200 mph so accidents with those cars are the same as an Indy car. So they need similar safety strengths and that's where the unified chassis concept came from. It was first provoked by safety, but then we were looking at it harder and commercially it makes a lot of sense. So our proposal is for a common chassis in IndyCar and Indy Lights to be used for the next three to five years. Economically, that would be a great boon to the teams.

© Lola Cars

Charlsey said Lola has been investigating the best way for Lola to build its new Indy cars in the United States.

"We will build the car in America," Charsley confirmed. "We will produce the car in America and more than likely in or around Speedway, Indiana. This will also be the first time Lola Indy cars will be sold in dollars. Fluctuations in the exchange rate can be a good thing and a bad thing so we will remove that from the equation."

Managing director Brundle expanded on Lola's plans to establish a manufacturing center in the United States, most likely as Charlsey says in Indiana.

"There are probably three different business models and one of them comes out as a financial balance," Brundle said. "We have the option to look at our own assembly facility. We have a huge bank of historical business partners in America that are still active with us and since we've started investigating the IRL program we've been approached by a whole host of new technical supppliers. We've had a lot of discussions and a lot of good meetings about using American labor and American companies to set up our own facility more likely in Indiana, but there are other options.

"We've had meetings with the people from the state of Indiana and we've had meetings with people who are pushing hard to promote the town of Speedway. There are incentives from the state and from the town of Speedway to be located there. We've now reached a point where we can't progress any further on those discussions until the IRL's decision is made. But we're nicely lined up in the background. There is a good business model there. It's undoubtedly going to be to use American labor in America and to pay taxes in America.

"The safety-related design work will be done at Huntingdon in England because that's where our technical facility is located," Brundle added. "Things like the safety cell and crash structures will be designed and manufactured in the UK initially. The first two or three cars will also be built in the UK and we will then go into the American process."

Brundle and Charsley were happy with their meeting with Randy Bernard at Long Beach.

"We feel Randy listened and that's all we asked him to do," Bundle commented. "He has a group of seven advisors and we wouldn't expect anything other than his group of seven will make the decision. But he listened to us with interest."

Added Lola's chairman Martin Birrane:

"Should Lola be involved in the future of IndyCar it would be a great pleasure for me to once again deal with a number of team owners that we have worked with successfully in the past and new entities combined. Many of the Indy car team principals have won with Lola products and know that we produce spectacular and safe race cars."

Auto Racing ~ Gordon Kirby

Copyright 2010 ~ All Rights Reserved

Copyright 2010 ~ All Rights Reserved

Top of Page